· Hugo · Customizing · 11 min read

Why Are Bicycles So Expensive? (Complete Cost Breakdown)

Bicycles can cost anywhere from $200 to $15,000+. Why are they so expensive? Learn what drives bicycle prices, from materials and components to labor and brand markup, and understand what you're actually paying for.

You’re shopping for a bicycle and shocked by the prices. A basic bike costs $300-$500, mid-range bikes are $1,000-$3,000, and high-end bikes can exceed $10,000. Why are bicycles so expensive?

The answer involves multiple factors: materials, components, manufacturing, research and development, brand markup, and retail margins. Understanding what drives bicycle prices helps you make informed purchasing decisions and understand what you’re actually paying for.

In this guide, I’ll break down the complete cost structure of bicycles, explain why prices vary so dramatically, and help you understand where your money goes when buying a bike.

Bicycle Price Ranges: What to Expect

In 2026, the definitions for bicycle price tiers have shifted upward significantly compared to historical standards [1]. High-quality entry-level machines are now expected to cost between $500 and $1,000. While it is possible to start road riding for as little as $350, spending slightly more is recommended for better quality [1]. The mid-range tier is increasingly defined as $3,000 to $5,000 in current market conditions [1]. The high-end category typically begins above $5,000, while premium or “S-tier” superbikes often exceed $10,000, with some models reaching as high as $16,499 [1].

Entry-Level Bicycles: $500-$1,000 [1]

- High-quality entry-level machines

- Can start as low as $350, but $500+ recommended for better quality

- Better components than historical entry-level

- Suitable for regular road riding

Mid-Range Bicycles: $3,000-$5,000 [1]

- Previously $500-$2,000 range now considered high-entry or low-mid level

- Better components and frame materials

- Good for regular riding and performance-oriented use

High-End Bicycles: $5,000+ [1]

- Premium components

- Carbon fiber frames

- Performance-oriented

- Examples: Premium bikes in the $13,000 to $15,000+ range, such as the Cannondale Synapse Lab71 or BMC Teammachine R 01 LTD [1]

Premium/Luxury Bicycles: $10,000-$16,499+ [1]

- Top-tier components

- High-end carbon or custom frames

- Professional-grade performance

- Elite “S-tier” models range from $10,000 to over $16,499

Cost Breakdown: Where Your Money Goes

The specific percentages provided (e.g., 30-40% for frames) are not found in the sources [2]. However, the sources confirm that:

- Material and Personnel costs are the primary drivers of bike prices [2]

- Material costs are a major focus for manufacturers seeking to improve margins, especially in the expensive e-bike segment [2]

- Inventory surpluses are currently weighing heavily on profits, with some major manufacturers seeing profit drops of 45% in recent years [2]

- Due to high inventory and financial pressure, manufacturers are being advised to streamline their product models by one-third to reduce working capital [5]

Frame (30-40% of Cost)

The frame is the “backbone” of the system and typically represents the largest single investment [1, 2]. For premium models, the frame alone can cost several thousand dollars, such as the Santa Cruz Bronson 5 CC at $4,049.

Materials:

The provided sources do not list specific raw material costs in dollar amounts for steel, aluminum, or carbon fiber [2]. However, they do provide qualitative cost insights:

- Aluminum: The standard for affordable bikes as it is cheaper to produce than carbon fiber [2]

- Carbon Fiber: Offers a high strength-to-weight ratio but is significantly more expensive, used primarily in high-end and premium tiers [2]

- Steel: Noted for classic aesthetics and a unique “zingy” ride quality [2]

- Titanium: Noted as a “large investment” due to the difficulty of the manufacturing process [2]

Material costs are currently considered the largest cost block for manufacturers alongside personnel [2]. Manufacturers are currently focusing on reducing material costs to improve margins [2]

Manufacturing:

- Frame design and engineering

- Tooling and molds (especially carbon)

- Welding or bonding processes

- Quality control and testing

Why Frames Are Expensive:

- Research and development costs

- Material costs (especially carbon fiber)

- Labor-intensive manufacturing

- Quality control and testing

- Policy and tariff impacts have forced brands to evaluate alternative sourcing, moving some frame production from Asia to facilities in Portugal, Italy, and Germany [5]

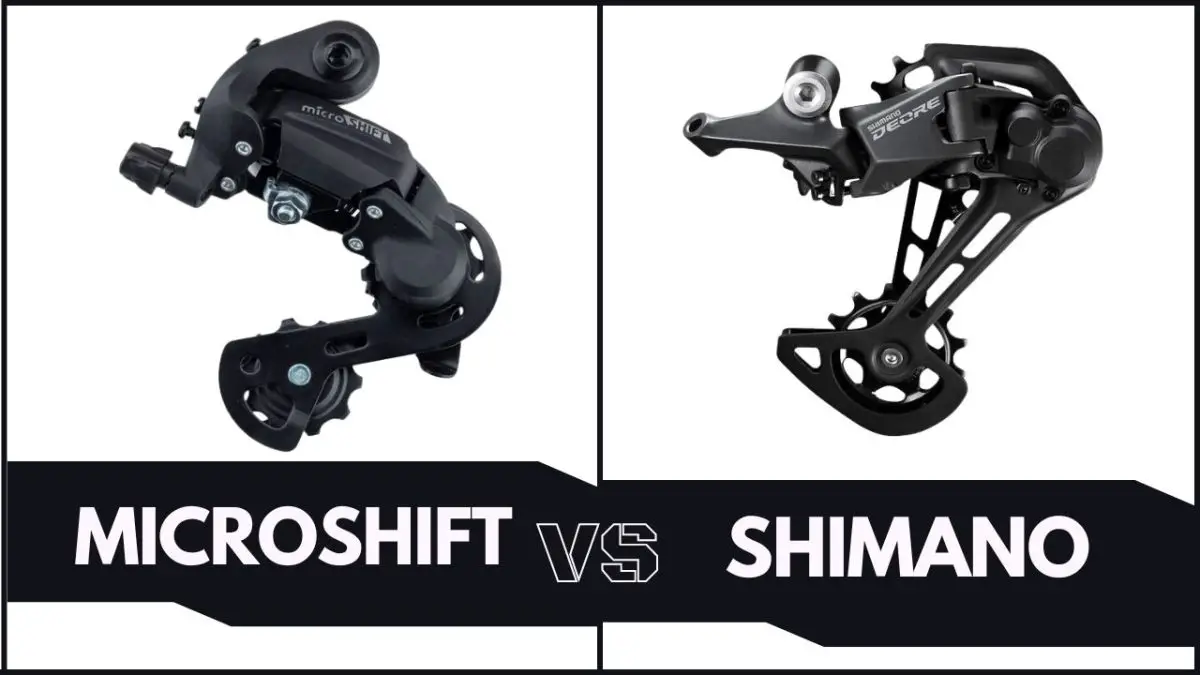

Components/Drivetrain (30-40% of Cost)

This category, often referred to as the “groupset,” includes derailleurs, shifters, and the crankset. High-end groupsets like Shimano Dura-Ace or SRAM Red frequently fall within this 30-40% range of the total bike’s MSRP. Groupsets typically account for 30% to 40% of a bicycle’s total cost due to the precision engineering and high-grade materials (such as titanium and carbon) required [1, 2].

Groupset Pricing (Shimano, SRAM, Campagnolo):

Retail prices for complete electronic groupsets in 2026 (based on RRP) are as follows [3]:

- Shimano Ultegra Di2: Approximately $2,400 [3]

- Shimano Dura-Ace Di2: Approximately $4,300 [3]

- SRAM Force AXS: Approximately $2,176 [3]

- SRAM Red AXS: Approximately $4,090 [3]

- Campagnolo Super Record S Wireless: $4,299 [3]

- Campagnolo Super Record Wireless: $5,399 (flagship model) [3]

The sources do not provide standalone retail prices for entry-level groupsets like Shimano Claris, Sora, or 105, though they note these are commonly specced on bikes in the $1,000–$3,500 range [1]

Components Include:

- Derailleurs (front and rear)

- Shifters/brake levers

- Crankset and chainrings

- Cassette

- Chain

- Brakes (rim or disc)

Why Components Are Expensive:

- Precision engineering

- Material costs (titanium, carbon, high-grade aluminum)

- Research and development

- Brand markup (Shimano, SRAM, Campagnolo)

- Electronic shifting (Shimano Di2 and SRAM eTap/AXS) has significantly raised the floor for high-end groupset pricing

- High-end prices often include integrated power meters, which were previously third-party additions

Current Market Context:

In 2026, the industry is still recovering from a “bullwhip effect” that led to surplus stock. As a result, many groupsets are seeing discounts of 20% to 40% at the retail level as manufacturers like Shimano work through elevated distributor inventories.

Wheels (10-20% of Cost)

Wheels are a significant cost driver, particularly with the shift to carbon fiber rims and precision hubs. Individual components and wheelsets typically account for 20% to 40% of a bicycle’s total retail cost, with wheels alone representing 10% to 20% of the investment [1, 2]. For example, a high-end DT Swiss ARC 1100 wheelset retails for approximately $2,800, which aligns with this percentage on a $14,000 professional-grade bike.

Wheel Types:

Specific retail price ranges for individual components like saddles, handlebars, stems, and pedals are not explicitly detailed in the sources [2]. The sources do provide pricing for high-end wheelsets:

- Wheelsets: Premium carbon options like the Bora Ultra WTO Matt Edition cost $4,149, while the standard Bora WTO version is $2,949 [2]

- General Component Trends: Manufacturers expect component prices to continue rising by 5–10% through the end of 2025 [2]

- Key Component Segments: The component market includes frames, saddles, rims, brakes, and pedals [2]

Cost Factors:

- Rim material (aluminum vs carbon)

- Hub quality and bearings

- Spoke count and quality

- Labor (hand-built vs machine-built)

Other Components (10-20% of Cost)

Additional Components:

- Saddle: $30-$300+ - Standard models for casual or fitness riding typically fall between $30 and $100, while premium/performance models with lightweight carbon-railed racing saddles occupy the $100 to $300+ tier [2]

- Handlebar/Stem: $50-$500+ - Basic aluminum bars and stems for commuters or entry-level mountain bikes start at roughly $50, while specialized or integrated cockpits can cost up to or over $500 [2]

- Tires/Tubes: $50-$200+ - Standard sets (two tires and two tubes) generally cost between $50 and $100, while performance and tubeless tires can push the cost for a pair and sealant/tubes over $200 [2]

- Pedals: $20-$300+ - Entry-level flat pedals or basic plastic models start as low as $20, while performance-grade pedals typically range from $150 to $300+ due to the use of carbon bodies and titanium spindles [2]

- Brakes: Included in groupset or $100-$500+

Labor and Assembly (5-10% of Cost)

This covers manufacturing labor (welding, bonding, quality control) and retail-level assembly and tuning.

Manufacturing Labor:

- Frame building/welding

- Component installation

- Quality control

- Assembly and testing

Retail Assembly:

- Bike shop assembly

- Tuning and adjustment

- Quality checks

Research and Development (5-10% of Cost)

This includes aerodynamic testing in wind tunnels, material research, and prototyping, costs that are spread across the production run.

R&D Costs Include:

- Frame design and engineering

- Aerodynamic testing

- Material research

- Component development

- Testing and prototyping

Why R&D Matters:

- Innovation drives prices

- Testing ensures safety and performance

- Development costs are spread across production

Brand Markup and Retail Margin (20-40% of Cost)

This percentage covers brand marketing, distribution, and bike shop overhead (staff and inventory costs).

Brand Markup:

- Brand reputation and marketing

- Distribution costs

- Profit margins

Retail Margin:

- Bike shop overhead

- Staff costs

- Inventory costs

- Profit margins

Current Market Context:

Due to a “bullwhip effect” that flooded the market with surplus stock between 2023 and 2025, retailers have been forced to offer heavy discounts of 20% to 40%. This directly erodes the brand markup and retail margin tier. To recapture profit, many brands are now engineering their own components (e.g., Specialized e-drivetrains or Scott’s Syncros parts) to reduce the bill of materials and capture a higher share of the total margin.

Why High-End Bicycles Cost So Much

1. Premium Materials

Carbon Fiber:

- Expensive raw materials

- Labor-intensive manufacturing

- Complex molding processes

- Quality control requirements

Titanium:

- Expensive raw materials

- Difficult to work with

- Specialized welding required

- Limited production

High-Grade Aluminum:

- Better alloys cost more

- More complex manufacturing

- Better performance characteristics

2. Premium Components

Top-Tier Groupsets:

- Shimano Dura-Ace: $2,500-$3,500+

- SRAM Red: $2,000-$3,000+

- Campagnolo Super Record: $3,000-$4,000+

Why Premium Components Cost More:

- Lighter weight (more expensive materials) - For example, Dura-Ace uses an aluminum front derailleur cage instead of steel

- Better performance (precision engineering)

- Durability (higher quality materials)

- Brand prestige

- Integrated features like electronic shifting (Di2) and professional power meters

3. Research and Development

Aerodynamics:

- Wind tunnel testing

- Computational fluid dynamics

- Prototype development

Weight Reduction:

- Material research

- Design optimization

- Testing and validation

Performance:

- Component development

- Frame stiffness optimization

- Ride quality tuning

4. Limited Production

Custom/Small-Batch Frames:

- Higher per-unit costs

- Specialized tooling

- Limited economies of scale

Hand-Built Wheels:

- Labor-intensive

- Higher quality control

- Custom specifications

Factors That Drive Price Differences

Material Costs

Current raw material costs for bicycle frames in 2026 are categorized by material performance and manufacturing complexity, with carbon fiber remaining the most significant investment for high-end production [1, 2].

Frame Material Cost Comparison

| Material | Cost Level | Characteristics |

|---|---|---|

| Aluminum | Most Affordable | Lower production costs compared to carbon |

| Steel | Affordable | Classic aesthetics and unique 'zingy' ride quality |

| Carbon Fiber | Expensive | High strength-to-weight ratio, used primarily in high-end and premium tiers |

| Titanium | Large Investment | Extreme difficulty of working the material |

Market Context:

While the base costs for raw materials have established benchmarks, the total cost of bringing a frame to market in 2026 has been influenced by several major industry shifts. Cumulative US tariffs through 2025 have forced brands to evaluate alternative sourcing and manufacturing footprints, moving some frame production for high-end models from Asia to facilities in Portugal, Italy, and Germany [5]. Following a three-year industry downturn (2023–2025), brands in 2026 are intentionally reducing the number of models (SKUs) and offering fewer “top-spec” configurations to bring retail prices down to levels the market can absorb [5]. Due to high inventory and financial pressure, manufacturers are being advised to streamline their product models by one-third to reduce working capital [5].

Component Quality

Groupset Tiers (2026 RRP):

- High-end: Shimano Ultegra Di2 R8100 (

$2,400), SRAM Force AXS ($2,176) [3] - Premium: Shimano Dura-Ace Di2 R9200 (

$4,300), SRAM Red AXS ($4,090), Campagnolo Super Record S Wireless (~$4,299) [3] - Top-tier: Campagnolo Super Record Wireless (~$5,399) [3]

- Entry-level: Shimano Claris, Sora, and 105 are commonly specced on bikes in the $1,000–$3,500 range [1]

Brand Reputation

Premium Brands:

- Higher markup for brand value

- Marketing and sponsorship costs

- Research and development investment

- Customer support and warranty

Value Brands:

- Lower markup

- Focus on value proposition

- Less marketing overhead

- Still good quality at lower prices

Are Expensive Bicycles Worth It?

When Premium Bikes Make Sense:

Serious Cycling:

- Racing or competitive cycling

- Performance is priority

- Marginal gains matter

Long-Term Investment:

- Plan to ride for many years

- Better durability and reliability

- Higher resale value

Specific Needs:

- Custom fit requirements

- Specialized use cases

- Professional requirements

When Budget Bikes Are Fine:

Casual Riding:

- Occasional recreational use

- Short commutes

- Fitness riding

Learning:

- First bike

- Learning to ride

- Testing interest

Budget Constraints:

- Limited budget

- Value is priority

- Entry-level meets needs

How to Get Better Value

1. Buy Previous Year Models

Typical discount percentages in the current market (2025–2026) are significantly higher than historical 15–30% ranges due to an industry-wide inventory crisis [2]. Manufacturers and retailers are using “heavy discounts” for clearance and overstock, reaching 25% to 47% [2]. Current real-world examples include:

- General Sales: Many models are discounted between 25% and 39% [2]

- Clearance/High Inventory: Specific examples include the Scott Patron eRIDE 900 at 47% off and the Cannondale Moterra Carbon 2 at 39% off [2]

2. Consider Used Bikes

- Significant savings

- Research thoroughly

- Check condition carefully

3. Buy Frame and Build Up

- Can save money

- Choose components yourself

- Requires knowledge and time

4. Shop Sales

Typical discount percentages in the current market (2025–2026) are significantly higher than historical 15–30% ranges due to an industry-wide inventory crisis [2, 5]. Manufacturers and retailers are using “heavy discounts” for clearance and overstock, reaching 25% to 47% [2]. Current real-world examples include:

- General Sales: Many models are discounted between 25% and 39% [2]

- Clearance/High Inventory: Specific examples include the Scott Patron eRIDE 900 at 47% off and the Cannondale Moterra Carbon 2 at 39% off [2]

5. Consider Value Brands

- Good quality at lower prices

- Less brand markup

- Still reliable and functional

Bicycle Pricing FAQs

Why do bicycles cost so much?

Bicycles are expensive due to materials (especially carbon fiber), premium components (groupsets, wheels), research and development costs, manufacturing labor, and brand/retail markup. Frame and components typically make up 60-80% of the cost.

What's the most expensive part of a bicycle?

The frame and groupset (drivetrain components) are typically the most expensive parts, each accounting for 30-40% of the total cost. Premium carbon frames and high-end groupsets can cost thousands of dollars.

Are expensive bicycles worth the money?

For serious cyclists and performance-oriented riders, expensive bicycles offer better performance, lighter weight, and improved durability. For casual riders, mid-range or entry-level bikes often provide sufficient quality at lower prices.

Why are carbon fiber bikes so expensive?

Carbon fiber is expensive due to high raw material costs, labor-intensive manufacturing (hand-laid carbon, complex molds), research and development, and quality control requirements. Carbon frames can cost 3-5x more than aluminum frames.

How much should I spend on a bicycle?

High-quality entry-level bikes ($500-$1,000, can start at $350) are recommended for regular road riding. Mid-range bikes ($3,000-$5,000) offer better quality for performance-oriented use. High-end bikes ($5,000+) are for serious cyclists. Premium S-tier superbikes ($10,000+) offer professional-grade performance. Spend based on your needs, not just your budget.

Do expensive bikes last longer?

Generally yes—premium materials and components are more durable. However, proper maintenance matters more than price. A well-maintained mid-range bike can last as long as a poorly maintained expensive bike.

Can I build a bike cheaper than buying one?

Usually not—manufacturers get volume discounts on components. Building from parts typically costs more unless you're using used components or getting significant deals. However, you can customize exactly what you want.

Why do some bikes cost $10,000+?

Ultra-premium bikes ($10,000+) feature top-tier components (Dura-Ace, Red), premium carbon frames, custom builds, limited production, and brand prestige. The marginal performance gains are small, but materials and craftsmanship justify the price for serious cyclists.

Summary: Understanding What You’re Paying For

Bicycles are expensive because of materials, components, manufacturing, R&D, and markup. Understanding the cost breakdown helps you make informed decisions and find the right balance between price and quality.

Key Cost Drivers:

- Frame (30-40%): Materials and manufacturing complexity

- Components (30-40%): Groupset quality and component selection

- Wheels (10-20%): Material and build quality

- R&D and Markup (20-40%): Innovation, brand value, retail margins

Price Ranges:

- Entry-level: $500-$1,000 (high-quality entry-level, can start at $350 but $500+ recommended)

- Mid-range: $3,000-$5,000 (current market definition)

- High-end: $5,000+ (performance-oriented)

- Premium: $10,000-$16,499+ (S-tier superbikes)

Value Strategy: Buy based on your needs, not just your budget. For casual riders, entry-level or mid-range bikes offer good value. For serious cyclists, premium bikes justify their cost through performance and durability.

2026 Market Context:

Typical discount percentages in the current market (2025–2026) are significantly higher than historical 15–30% ranges due to an industry-wide inventory crisis [2, 5]. Manufacturers and retailers are using “heavy discounts” for clearance and overstock, reaching 25% to 47% [2]. Current real-world examples include the Scott Patron eRIDE 900 at 47% off and the Cannondale Moterra Carbon 2 at 39% off [2]. The industry is moving toward a recovery characterized by value rather than volume, and brands are increasingly reducing the number of models (SKUs) and offering less “top-spec” equipment to bring retail prices down to a level the market can absorb [5].

The E-Bike Factor:

Revenues in 2026 are increasingly driven by electrification, which carries higher average selling prices due to motor and battery technology. In Germany, for example, the average bike price tripled between 2011 and 2023 due to this shift. As electrification continues to grow, e-bike components (motors and batteries) are taking a larger share of the cost, often making it “not make sense to buy a normal bike” at certain price points. The shift toward electrification is also driving higher average prices for components like tires and wheels, which must be engineered to handle increased torque and weight.